AKCP Thermal Map Sensor (THMS-V2 / CTHMS-V2)

Monitor temperature differential between front and rear of your cabinet.

- Temperature only

- Dual Temperature and Humidity

- Check for cabinet hotspots

Detect Hotspots In Your Cabinet

Datacenter monitoring with thermal map sensors helps identify and eliminate hotspots in your cabinets by identifying areas where temperature differential between front and rear are too high.

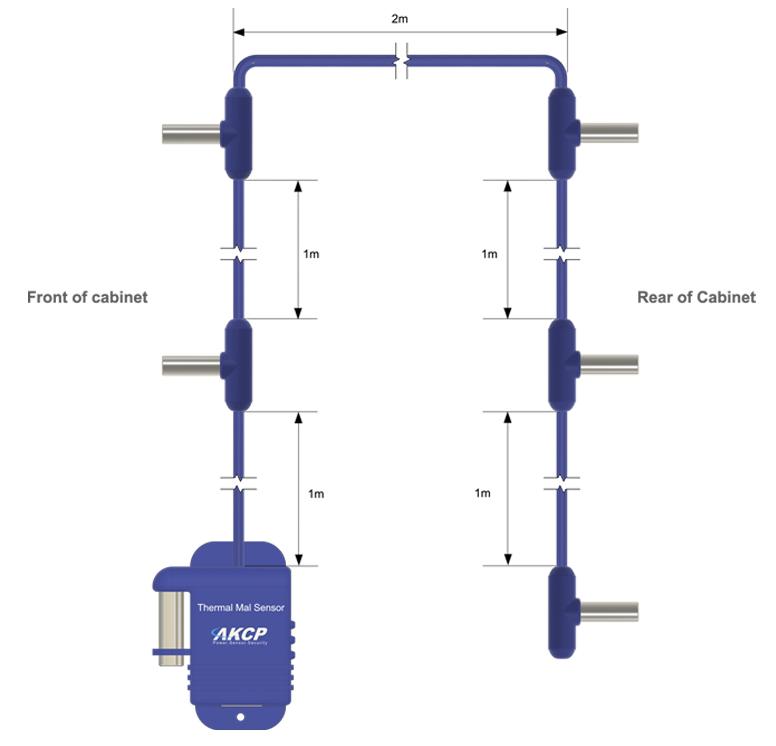

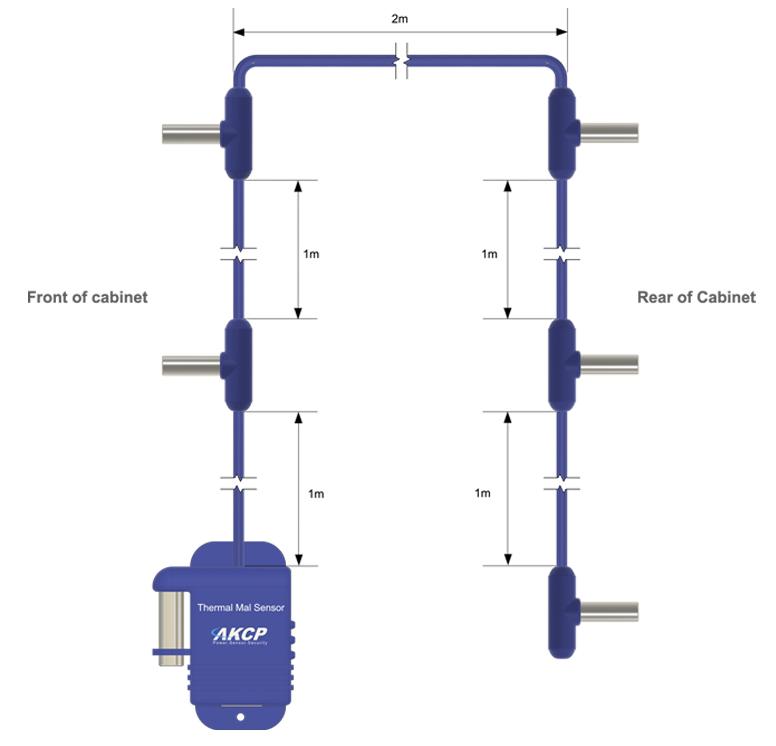

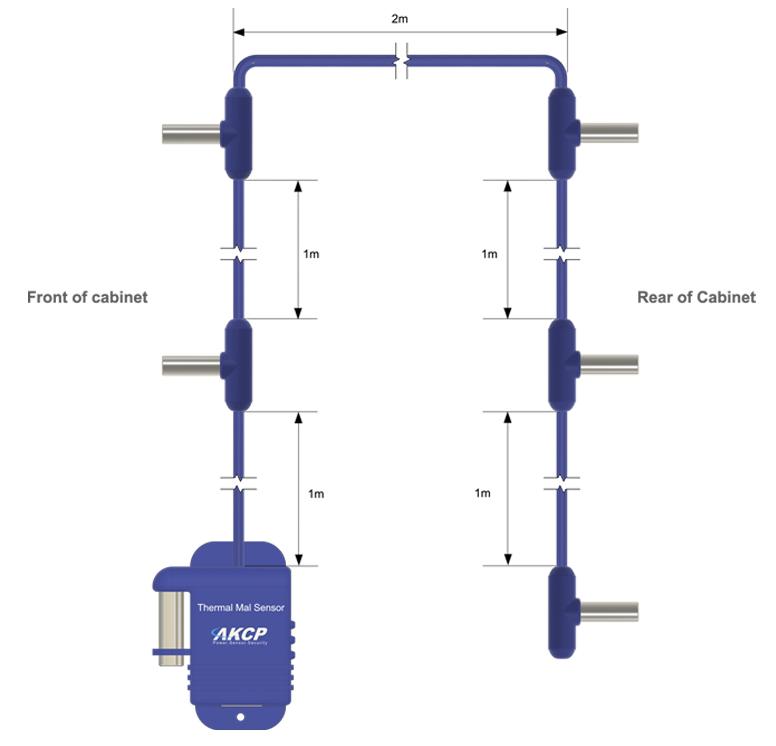

AKCP Thermal Map Sensor consists of a string of 6 temperature sensors and an optional 2 humidity sensors. Pre-wired to be easily installed in your cabinet, they are placed at the top, middle, and bottom - front and rear of the cabinet. This configuration of sensors monitors the air intake and exhaust temperatures of your cabinet, as well as the temperature differential from the front to the rear. Use thermal map sensors to identify cabinet hot spots and problem areas. AKCP Thermal Map Sensors are easy to install, come pre-wired, and are ready to mount with magnetic, cable ties, or ultra-high bond adhesive tape to hold them in position on your cabinet. Mount each sensor on the front and rear doors of your perforated cabinet so they are exposed directly to the airflow in and out of the rack. On sealed cabinets, they can still be mounted on the inside and give the same monitoring of temperature differential between front and rear, and ensure that airflow is distributed across the cabinet. AKCP Thermal Map Sensor connects to AKCP sensorProbe+ base units. Extendable up to a maximum of 15 meters cable length, you can monitor multiple cabinets from a single IP address. Up to 16 thermal maps can be connected to a single SPX+.

Advantages Of Thermal Map Sensors

Obstructions Within The Cabinet

Cabling or other obstructions can impede the flow of air causing high-temperature differentials between the inlet and outlet temperatures. The cabinet analysis sensor with pressure differential can also help analyze airflow issues.

Server And Cooling Fan Failures

As fans age, or fail, the airflow over the IT equipment will lessen. This leads to higher temperature differentials between the front and rear.

Insufficient Pressure Differential To Pull Air Through The Cabinet

When there is an insufficient pressure differential between the front and rear of the cabinet, airflow will be less. The less cold air flowing through the cabinet, the higher the temperature differential front to rear will become.

Power Usage Effectiveness (PUE)

When the data is combined with the power consumption from the in-line power meter you can safely make adjustments in the data center cooling systems, without compromising your equipment, while instantly seeing the changes in your PUE numbers.

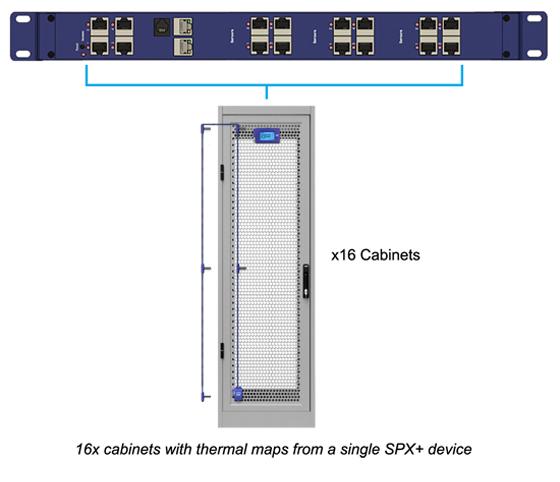

Multiple Cabinets

Monitor up to 16 cabinets from a single IP address. With a 16 sensor port SPX+, you consume only 1U of rack space and save costs by having only one base unit. Thermal map sensors can be extended up to 15 meters from the SPX+.

Datacenter monitoring with thermal map sensors helps identify and eliminate hotspots in your cabinets by identifying areas where temperature differential between front and rear are too high.

AKCP Thermal Map Sensor consists of a string of 6 temperature sensors and an optional 2 humidity sensors. Pre-wired to be easily installed in your cabinet, they are placed at the top, middle, and bottom - front and rear of the cabinet. This configuration of sensors monitors the air intake and exhaust temperatures of your cabinet, as well as the temperature differential from the front to the rear. Use thermal map sensors to identify cabinet hot spots and problem areas. AKCP Thermal Map Sensors are easy to install, come pre-wired, and are ready to mount with magnetic, cable ties, or ultra-high bond adhesive tape to hold them in position on your cabinet. Mount each sensor on the front and rear doors of your perforated cabinet so they are exposed directly to the airflow in and out of the rack. On sealed cabinets, they can still be mounted on the inside and give the same monitoring of temperature differential between front and rear, and ensure that airflow is distributed across the cabinet. AKCP Thermal Map Sensor connects to AKCP sensorProbe+ base units. Extendable up to a maximum of 15 meters cable length, you can monitor multiple cabinets from a single IP address. Up to 16 thermal maps can be connected to a single SPX+.

Advantages Of Thermal Map Sensors

Obstructions Within The Cabinet

Cabling or other obstructions can impede the flow of air causing high-temperature differentials between the inlet and outlet temperatures. The cabinet analysis sensor with pressure differential can also help analyze airflow issues.

Server And Cooling Fan Failures

As fans age, or fail, the airflow over the IT equipment will lessen. This leads to higher temperature differentials between the front and rear.

Insufficient Pressure Differential To Pull Air Through The Cabinet

When there is an insufficient pressure differential between the front and rear of the cabinet, airflow will be less. The less cold air flowing through the cabinet, the higher the temperature differential front to rear will become.

Power Usage Effectiveness (PUE)

When the data is combined with the power consumption from the in-line power meter you can safely make adjustments in the data center cooling systems, without compromising your equipment, while instantly seeing the changes in your PUE numbers.

Multiple Cabinets

Monitor up to 16 cabinets from a single IP address. With a 16 sensor port SPX+, you consume only 1U of rack space and save costs by having only one base unit. Thermal map sensors can be extended up to 15 meters from the SPX+.

Specification

Temperature

Humidity

General

Ordering Information

Temperature

| Never needs Calibration | |

| Measurement Range | -40°C to +75°C / -40°F to +167°F |

| Measurement Resolution | 0.1°C increments / 0.2°F increments |

| Measurement Accuracy | Maximum ±0.3 at -40ºC, minimum ±0.3 at +25ºC to +75ºC Maximum ±0.6 at -40ºF, minimum ±0.6 at +77ºF and to +167ºF |

| Communication Cable | RJ45 jack to temperature sensor using UTP CAT5/6 |

| Sensor Type | semiconductor microprocessor controlled |

| Power Source | powered by the sensorProbe+. No additional power is needed. |

| Power Consumption | Typical 75 mWatt, 15 mA |

| Number of sensors | 6 temperature sensors |

Humidity

| Measurement range | 0 to 100% Relative humidity |

| Resolution | 1% for the sensorProbes and 0.1% for the securityProbe units. |

| Accuracy | 25°C ±3% |

| Power Source | powered by the sensorProbe. No additional power is needed. |

| Power Consumption | Typical 65 mWatt, 13 mA |

| Number of sensors | 2 Humidity sensors |

General

| Maximum cable length | 18 meters / 60 feet with approved low capacitance shielded UTP cable |

| Auto-sense | sensorProbe+ unit auto-detects the presence of the Thermal Map Sensor and configures the unit automatically. |

| Important Note | Thermal Map Sensor is only compatible with the sensorProbe+ platform. |

Ordering Information

| Product Model | Order Number | Description |

|---|---|---|

| Thermal Map Sensor | ||

| THMS-V2 | 949015 | "Temperature and Humidity Map Sensor String of 3x Temperature and 1x Humidity sensor Pre wired for easy installation" |

| CTHMS-V2 | 940215 | "Cabinet Temperature and Humidity Map 2x strings of 3x Temperature and 1x Humidity sensors for front and rear of the cabinet. 1x Sensor Splitter adapter box to connect both strings to 1 sensor port" |

| CAS | 944160 | Cabinet analysis sensor (thermal map plus differential air pressure sensor) |

| DAPS | 944161 | Differential Air Pressure Sensor |

| Thermal Mapping Accessories | ||

| MMK | 940167 | "Magnetic Mounting Kit Easily mount sensors on cabinets and detach for relocation as needed." |

| SSB | 949016 | "Sensor Splitter adapter box Connect 3 sensor inputs (2x thermal map strings and 1x current meter) to a single sensor port." |

Customers who viewed this item also viewed

Customers who viewed this item also viewed

Properties

Properties Description

Description Further Information

Further Information

Properties

Properties Description

Description PDF

PDF